"Made in Zhejiang" product certification, standards, advanced technical indicators, quality commitment, after-sales service

Source: ZHEJIANG DONGLI ELECTRIC APPLIANCE CO.,LTDPublication time:2021-04-23

Advanced technical indicators of "made in Zhejiang" standard

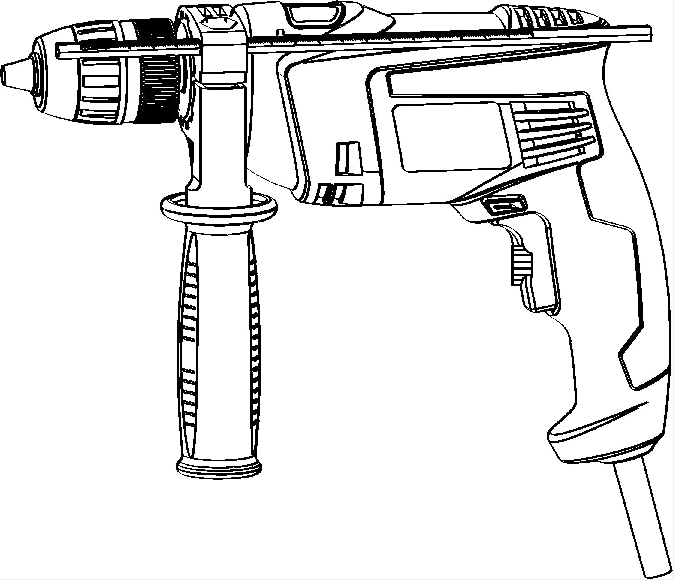

Product Name: impact electric drill Executive standard: T / zzb 0419-2018

|

Technical index |

Zhejiang manufacturing standard

|

National standard

|

international standard — |

|

Rated output power (W)

|

≥ 260,320,400,450, |

≥220、280、350、430 |

— |

|

Spindle accuracy (radial run out of mandrel) |

Not more than 0.4mm |

Not more than 0.5mm |

— |

|

High and low temperature cycle performance |

Keep in the temperature control box of 70 ℃ and - 20 ℃ for 7 hours respectively, and the product is normal |

— |

— |

|

Dust resistance |

After 5000 cycles of no negative pressure dust test, there is no mechanical and electrical failure during and after the test. |

— |

— |

|

Rotating load endurance |

The axial force of 200N applied to the product shall be operated according to the specified cycle, and the operation of the first and second carbon brushes shall not be less than 1620 cycles. |

— |

— |

|

Emergency stop |

The percussion electric drill stops completely for one cycle within 15s of no-load and 0.5s of brake, and runs continuously for 5000 cycles without mechanical failure. |

— |

— |

"Made in Zhejiang" standard takes the satisfaction of high-quality and assured consumption as its own duty, and innovates the requirements of "quality commitment" to ensure that the commitment of each standard in quality assurance, after-sales service, etc. is higher than the overall level of the industry.

Exhibitors: Zhejiang Dongli Electric Co., Ltd

Advanced technical indicators of "made in Zhejiang" standard

Product Name: hand held electric drill Executive standard: T / zzb 0417-2018

|

Technical index |

Zhejiang manufacturing standard

|

National standard

|

international standard — |

|

Spindle accuracy (radial run out of mandrel) |

Not more than 0.4mm |

Not more than 0.5mm |

— |

|

High and low temperature cycle performance |

Keep in the temperature control box of 70 ℃ and - 20 ℃ for 7 hours respectively, and the product is normal |

— |

— |

|

Dust resistance |

After 5000 cycles of no negative pressure dust test, there is no mechanical and electrical failure during and after the test. |

— |

— |

|

Rotating load endurance |

The axial force of 200N applied to the product shall be operated according to the specified cycle, and the operation of the first and second carbon brushes shall not be less than 1500 cycles. |

— |

— |

|

Stall |

The electric drill runs 15 times of locked rotor test continuously according to the circulation of locked rotor for 3S, idle running for 12s and shutdown for 15s, without any electrical fault. |

— |

— |

|

Emergency stop |

The electric drill stops completely for one cycle within 15s of no-load and 0.5s of brake, and runs continuously for 5000 cycles without mechanical failure. |

— |

— |

"Made in Zhejiang" standard takes the satisfaction of high-quality and assured consumption as its own duty, and innovates the requirements of "quality commitment" to ensure that the commitment of each standard in quality assurance, after-sales service, etc. is higher than the overall level of the industry.

Exhibitors: Zhejiang Dongli Electric Co., Ltd

Advanced technical indicators of "made in Zhejiang" standard

Product Name: stone cutting machine Executive standard: T / zzb0418-2018

|

Technical index |

Zhejiang manufacturing standard

|

National standard

|

international standard — |

|

Rated output power (W)

|

≥650 |

≥450 |

|

|

Specification: 110 cutting depth mm |

≥32 |

≥30 |

|

|

Rotating load endurance |

Under rated voltage, it is required to operate for at least 120 hours according to the cycle set for no-load 15s, rated load 30s and shutdown 15s |

|

|

|

Gear blocking |

According to the cycle operation of idling for 10s and locked rotor for 1s, it shall be able to withstand 60 consecutive locked rotor tests without electrical failure. |

|

|

|

Motor blocking |

According to the locked rotor for 3S, idling for 12s, shutdown for 15s, at least 20 times of blocking

|

|

|

"Made in Zhejiang" standard takes the satisfaction of high-quality and assured consumption as its own duty, and innovates the requirements of "quality commitment" to ensure that the commitment of each standard in quality assurance, after-sales service, etc. is higher than the overall level of the industry.

Exhibitors: Zhejiang Dongli Electric Co., Ltd

Instructions for electric drill / percussion electric

Manufacturer: Zhejiang Dongli Electric Appliance Co., Ltd

Address: No.29 Huacheng West Road, Xicheng, Yongkang

General safety warnings for AC hand-held electric tools:

Warning! Read all safety warnings, instructions, illustrations and regulations provided with the power tools. Failure to follow the instructions listed below can result in electric shock, fire and / or serious injury.

Keep all warnings and instructions for reference.

The term "electric tool" in the warning refers to the utility driven (wired) electric tool or battery driven (wireless) electric tool

a) Safety of the workplace

1) Keep the workplace clean and bright. Messy and dark places can cause accidents.

2) Do not operate electric tools in explosive environment, such as flammable liquid, gas or dust. Sparks from electric tools can ignite dust or gas.

3) Keep away from children and bystanders when operating electric tools. Inattention can cause you to lose control of the tool.

b) Electrical safety

1) The plug of electric tool must match the socket. Never modify the plug in any way. No change-over plug shall be used for electric tools to be grounded. Unmodified plugs and matching sockets will reduce the risk of electric shock.

2) Avoid contact with grounded surfaces, such as pipes, fins, and refrigerators. Grounding your body increases the risk of electric shock.

3) Do not expose electric tools to rain or humidity. Water entering electric tools will increase the risk of electric shock.

4) Do not abuse wires. Never handle, pull or unplug electric tools with flexible wires. Keep wires away from heat, oil, sharp edges, or moving parts. Damaged or twisted cords increase the risk of electric shock.

5) When using electric tools outdoors, use an extension cord suitable for outdoor use. Wires suitable for outdoor use will reduce the risk of electric shock.

6) If it is not possible to avoid operating electric tools in a humid environment, a power supply with RCD protection shall be used. The use of RCD can reduce the risk of electric shock.

c) Personal safety

1) Keep alert, pay attention to the operation and keep awake when operating electric tools. Do not operate power tools when you are tired or in the presence of drugs, alcohol or therapeutic reactions. Negligence in the operation of electric tools can cause serious personal injury.

2) Use personal protective equipment. Always wear goggles. Protective devices, such as dust masks, anti-skid safety shoes, helmets, hearing protection and other devices under appropriate conditions, can reduce personal injury.

3) Prevent accidental starting. Make sure the switch is in the off position before connecting the power supply and / or battery pack, picking up or carrying tools. Danger can be caused by placing fingers on the switch to carry the tool or by energizing the switch when it is on.

4) Remove all adjustment keys or wrenches before turning on the power tool. Personal injury can result from wrenches or keys left on rotating parts of power tools.

5) Don't stretch your hands too much. Always pay attention to foothold and body balance. In this way, the electric tools can be better controlled under unexpected circumstances.

6) Dress appropriately. Do not wear loose clothing or accessories. Keep your hair and clothes away from moving parts. Loose clothing, accessories or long hair can get involved in moving parts.

7) If a device is provided for connection with chip removal and dust collection equipment, ensure that they are well connected and properly used. The use of dust collection devices can reduce the risk caused by dust.

8) Don't let the familiarity of using tools frequently lead to carelessness and neglect the safety rules of tools. A careless move can cause serious injury in an instant.

d) Use and precautions of electric tools

1) Do not use electric tools reluctantly. Use appropriate electric tools according to the purpose. Choosing the right rated power tools will make you work more efficiently and safely.

2) If the switch does not turn on or off the power, the power tool cannot be used. Power tools that cannot be controlled by switches are dangerous and must be repaired.

3) Before any adjustment, accessory replacement or storage of power tools, the plug must be removed from the power supply and / or the battery pack (if removable) must be removed. This protective safety measure reduces the risk of accidental starting of electric tools.

4) Store the unused electric tools out of the reach of children, and do not allow people who are not familiar with the electric tools or do not understand these instructions to operate the electric tools. Electric tools are dangerous in the hands of untrained users.

5) Maintain electric tools and accessories. Check whether the moving parts are adjusted in place or stuck, check the damage of parts and other conditions affecting the operation of electric tools. If there is any damage, repair the electric tools before use. Many accidents are caused by poorly maintained electric tools.

6) Keep cutting tools sharp and clean. A well maintained tool with a sharp cutting edge is not easy to jam and is easy to control.

7) Select electric tools, accessories and tool heads according to the operation instructions and considering the operation conditions and the operation to be carried out. Using power tools for operations that are not compatible with their purpose may result in a hazardous situation.

8) Keep the handle and grip surface dry and clean and free of grease. In case of accident, the slippery handle can not guarantee the safety of holding and the control of tools.

e) Maintenance

1) The same spare parts shall be used by professional maintenance personnel to repair electric tools. This will ensure the safety of the electric tools repaired.

2) If it is necessary to replace the power cord, the manufacturer or its agent must

drill:/Public/kindeditor/attached/file/20200430/20200430095140_11833.zip